Insimbi engenasici iyinto esetshenziswa ngensimbi enzima emshinini. Kunezinkinga ezimbili eziyinhloko ekuguqukeni: Insimbi engenasici anamandla aphezulu okushisa aphezulu kanye nokuthambekela okuqinile komsebenzi, okulula ukugqoka nokunciphisa impilo yamathuluzi. Insimbi engenangqondo inobunzima obuphakeme, ama-chips akulula ukuwaphula, futhi kulula ukulimala. Izinga lemishini elinqunyelwe futhi lisongo lokuphepha kwe-opharetha. Ngakho-ke, ukwephula i-chip ngesikhathi sokujika nakho kuyinkinga evelele ngokwengeziwe. Emsebenzini wokukhiqiza wesikhathi eside wokuguqula izingxenye zensimbi engagqwali, ithuluzi lokuguqula insimbi elingagqwali liye lahlolwa

Ubulukhuni obuhlukile bensimbi engenacala ngokungenacala ngemuva kokwelashwa okushisa unethonya elikhulu ekusebenzeni. Ithebula 1 libonisa isimo sokujika sensimbi engu-3Cr13 ngobulukhuni obuhlukile ngemuva kokushiswa kokushisa ngethuluzi lokuguqula elenziwe nge-YW2 impahla eyenziwe nge-YW2. Kungabonakala ukuthi yize ubulukhuni bensimbi engenasisekelo ye-annealed martensitic buphansi, ukusebenza okuguqukayo kumpofu. Lokhu kungenxa yokuthi lokho okuqukethwe kuneplastiki enkulu nokuqina, ukwakheka okungalingani, ukunamathela okuqinile, futhi kulula ukukhiqiza imiphetho yokusika ngesikhathi senqubo yokusika, futhi akulula ukuthola ikhwalithi enhle ebusweni. . Ngemuva kokucimana nokugunda, okubonakalayo kwe-3cr13 nobulukhuni ngaphansi kwa-HRC30 kunokusebenza okungcono futhi kulula ukufeza ikhwalithi ephezulu yendawo. Yize ikhwalithi ephezulu yezingxenye icutshungulwa lapho ubulukhuni bukhulu kune-HRC30 kungcono, ithuluzi kulula ukugqoka. Ngakho-ke, ngemuva kokufaka okubonakalayo kwefektri, kwenziwa inqubo ecijile nenogubhu kuqala, futhi ubunzima bufinyelela ku-HRC25- 30, bese inqubo yokusika yenziwa.

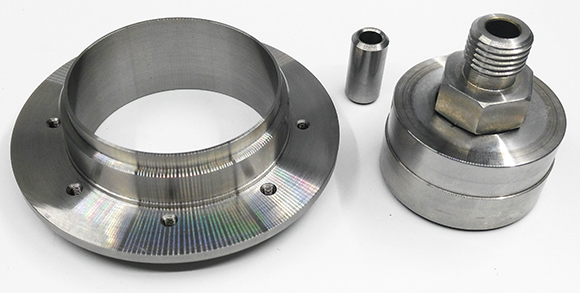

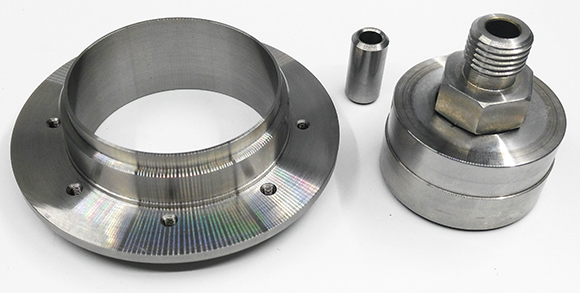

Ukukhetha kwezinto zethuluzi

Ukusebenza kokusika kokuqukethwe kwamathuluzi kuhlobene nokuqina kanye nokukhiqiza ithuluzi, kanye nokwakhiwa kwezinto zethuluzi kuthinta ukukhiqiza kanye nekhwalithi elolayo yethuluzi uqobo. Ngakho-ke, impahla yethuluzi kufanele ikhethwe njengethuluzi lethuluzi elinobulukhuni obuphezulu, ukumelana okuhle nokumelana nokuqina. Ngaphansi kwamapharamitha wokusika afanayo, umbhali wenze isivivinyo sokuqhathanisa ekuguqukeni kwamathuluzi wezinto ezimbalwa. Kungabonakala kusuka etafuleni 2 ukuthi ithuluzi lokuguqula elingaphandle eline-tic-ticn-tin composite coating blade inokuqina okuphezulu kanye nekhwalithi ephezulu yekhwalithi ephezulu ye-workpie. Okuhle, ukukhiqiza okuphezulu. Lokhu kungenxa yokuthi ama-blade alolu hlobo lwezinto ze-carbide ezihlanganisiwe zinamandla angcono nokuqina, futhi ngoba ingaphezulu linobunzima obukhulu futhi ligqoke ukumelana, futhi selibe yithuluzi elihle lokushisa, futhi selibe yithuluzi elihle lokuvula insimbi engagqwali I-CNC Lathes, kanye nokukhethwa kokuqala kwamathuluzi okuguqula angaphandle wensimbi ye-3cr13 insimbi engagqwali. Njengoba kungekho ukuncipha kwalokhu okuqukethwe, ukuhlolwa kokuqhathanisa kuThebula 2 kukhombisa ukuthi ukusebenza kokusika kwe-yw2 cemented Carbide nakho kuhle, ngakho-ke ibala le-yw2 lingasetshenziswa njengebala lokusika.

Ukukhetha i-angle yejometri kanye nokwakheka kwethuluzi

Ukuze uthole impahla enhle yamathuluzi, kubaluleke kakhulu ukukhetha i-geometric angle enengqondo. Lapho insimbi yensimbi engenacala, iJiyomethri yengxenye yokusika yethuluzi kufanele icatshangwe ngokukhethwa kwe-bake angle ne-angle emuva. Lapho ukhetha i-rake angle, izici ezinjengephrofayela umtshingo, ukuba khona noma ukungabikho kokuhlangana nokuhlangana okuhle nokubi kokuthambekela kwe-blace kufanele kubhekwe. Akunandaba nethuluzi, kufanele kusetshenziswe i-bacle engela enkulu lapho insimbi engagqwali. Ukwandisa i-rake angle yethuluzi kunganciphisa ukumelana okuhlangane nakho ngesikhathi sokusika kwe-chip nokususwa. Ukukhethwa kwe-angle yemvume akuqinile, kepha akufanele kube kuncane kakhulu. Uma i-angle yokuvunyelwa incane kakhulu, izodala ukungqubuzana okukhulu ngobubanzi bokusebenza, kukhulisa ubulukhuni bendawo ebekiwe kanye nokusheshisa ithuluzi lokugqoka. Futhi ngenxa yokuxabana okunamandla, umphumela wokuqina komsebenzi ngaphezulu kwensimbi engenasici kuyathuthukiswa. I-angle yokusiza ithuluzi akufanele ibe nkulu kakhulu. Uma i-angle yokusiza inkulu kakhulu, i-wedge angle yethuluzi iyancishiswa, amandla onqenqemeni wokusika ayancishiswa, futhi ukugqokwa kwethu kusheshiswa. Ngokuvamile, i-angle yokusiza kufanele ibe yinkulu kakhulu kunanini lapho icubungula insimbi evamile yekhabhoni. Ngokuvamile, lapho ijika ngensimbi engenacala, i-rake angle g0 yethuluzi mhlawumbe i-10 °-20 °. I-Angle Angle A0 ilungele ukuba ngu-5 ° ~ 8 °, futhi inani eliphakeme alikho ngaphezulu kwe-10 °.

Ngaphezu kwalokho, i-angle yokuthambekela ye-blade ls, i-angle engemihle ye-blader angle ingavikela ithiphu futhi ithuthukise amandla ebala. Ngokuvamile, i-G0 ikhethwe kusuka ku-10 ° kuya ku-30 °. I-angle engela yokungena kufanele ikhethwe ngokuya ngesimo sendawo yokusebenza, indawo ecubungula kanye nokufakwa kwamathuluzi. Ubulukhuni bendawo yokusika umkhawulo kufanele kube ra0.4 ~ 0.2μm.

Ngokuya ngesakhiwo samathuluzi, ngaphandle okuthambekele kwe-ARC Chip Chip Chip amathuluzi okuguqula angaphandle. I-Chip Curling Radius ekuphumeni kwethuluzi inkulu, futhi i-chip curling radius emaphethelweni angaphandle incane. Ama-chip aphendukela ebusweni azokwakhiwa futhi aphule, futhi ukuqhekeka kwe-chip kuhle. . Ithuluzi lokusika, i-angle yesibili yokudukiswa ingalawulwa ngaphakathi kwe-1 °, engathuthukisa izimo zokususa i-chip futhi yandise impilo yensiza yethuluzi.

Ukukhetha okunengqondo kwenani lokusika

Inani lokusika linomthelela omkhulu ekhwalithi ephezulu ye-workpiea, ukuqina kwethuluzi, nokukhiqiza okusebenzayo. Umbono wokusika ukholelwa ukuthi ijubane lokusika v linomthelela omkhulu ekushiseni kokusika nasekudakeni kwamathuluzi, kulandelwe yi-feed f, futhi i-ap incane kunazo zonke. Ukujula kwe-SUST AP kunqunywa ngosayizi womsebenzi owenziwayo ebusweni obucutshungulwe yithuluzi le-CNC Lathe. Kunqunywa ngosayizi wezinto ezibonakalayo ezingenalutho, ngokuvamile 0 ~ 3mm. Isivinini sokusika sezinto ezinzima ukuya kwa-Machine sivame ukuncipha kakhulu kunaleyo yensimbi ejwayelekile, ngoba ukwanda kwesivinini kuzodala ukugqoka okukhulu kwethuluzi, kanye nezinto zokwakha zensimbi ezahlukene zinezikhathi zazo ezihlukile zokusika. Lesi sivinini esifanelekile sokusika singamangalo kuphela esinganqunywa ngokuhlola noma ngokubonisana nolwazi olufanele. Lapho imishini enamathuluzi we-carbide anenkohliso, ngokuvamile income ukusika ijubane v = 60 ~ 80m / min.

Izinga lokuphakelayo F linomthelela omncane ekuweni kokuqina kwamathuluzi kunesivinini sokusika, kepha kuzothinta ijubane le-chip kanye nokususwa kwe-chip, ngaleyo ndlela kuthinte ubunzima bokusebenza komhlaba, futhi kuthinte ikhwalithi ephezulu yokucutshungulwa. Lapho ubulukhuni bendawo esetshenzisiwe bungaphezulu, f kufanele kube ngu-0.1 ~ 0.2mm / r.

Ngamafuphi, ngezinto ezinzima-kuya kokusebenza ngomshini, isivinini esiphansi sokusika kanye nenani lokuphakelwa okuphakathi livame ukusetshenziswa.

Khetha ukupholisa okufanele futhi uthambisa uketshezi

I-libricant epholile esetshenziselwa ukuguqula insimbi engenacala kufanele ibe nokusebenza okuphezulu okupholile, ukusebenza okunamandla okuthambeka okuphezulu nokuvumela okuhle.

Ukusebenza okuphezulu kokupholisa kuqinisekisa ukuthi inani elikhulu lokusika lingasuswa. Insimbi engenasici inobunzima obuphakeme, futhi kulula ukukhiqiza onqenqemeni owakhelwe ngaphakathi ngesikhathi sokusika nokuwohloka komhlaba. Lokhu kudinga ukuthambisa okupholile ukuze kube nokusebenza okuphezulu kokuthambisa kanye nokuvumela okungcono. Ukulungiswa okuvame ukusetshenziswa kwensimbi engagqwali kufaka uwoyela we-sulfurized, i-soybean oyela, uwoyela we-polur plus oleic acid noma uwoyela wemifino, ama-carbon plus amaminerali amaminerali, njll.

Uma kucatshangelwa ukuthi isibabule sinomphumela othile osonakalisayo eThethuluzi lomshini, uwoyela wemifino (njengamafutha e-soybean) kulula ukunamathisela ithuluzi lomshini futhi lihlanzeke. Umbhali wakhetha ingxube yekhabhoni enezandla ezine kanye ne-enjini kawoyela ngesilinganiso esingu-1: 9. Phakathi kwazo, ikhabhoni enezandla ezine inemvume enhle nokugcona okuhle kwamafutha enjini. Ukuhlolwa kuveze ukuthi lesi sithambisi esipholile silungele izinqubo zokuqeda nokuqeda izingxenye zensimbi ezingenasici ngezidingo ezincane zemifino, futhi zilungele kakhulu ukuguqulwa kwezingxenye zensimbi engagqwali.